Sanitary Filling Valve

Sanitary Valves

Our Sanitary Filling Valve is a hygienically designed valve used in automated liquid filling systems for industries such as food and beverage, dairy, and cosmetics. It precisely controls the flow of product during the bottle or container filling process, ensuring accurate volume, cleanliness, and speed.

The wetted steel parts are made of stainless steel 316L with a polished surface finish, ensuring excellent corrosion resistance, durability, and easy cleaning.

Features:

- Max. product pressure (depending on valve specifications):1000 kpa ( 10 bar )

- Min. product pressure:Full vacuum

- Temperature:-10℃ to 140℃ ( EPDM )

- Air pressure:5 bar to 7 bar

- Air connections:R1/8" BSP female thread

Materials:

- Product wetted steel parts:AISI 316L

- Other steel parts:AISI 304

- Plug stem:AISI 316L with hard chrome planted stem surface

- Product wetted seals:EPDM rubber

- Other seals:NBR

- Finish:Semi bright

Opening/Closing Time will be effected by the following:

- The air supply (air pressure)

- The length and dimensions of the air hose

- Number of valves connected to same air hose

- Use of single solenoid valve for serial connected air actuator functions

- Product pressure

-

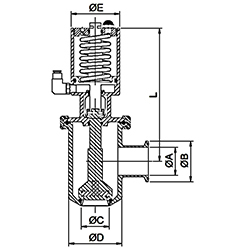

FVFilling Valve

SIZE ØA ØB ØC ØD ØE L 1”x1” 22.1 50.5 22.1 55 60 165 1”x1-1/2” 34.8 50.5 22.1 55 60 165 1”x2” 47.5 64.0 22.1 66 85 292 1-1/2”x1-1/2” 34.8 50.5 34.8 66 60 165 1-1/2”x2” 47.5 64.0 34.8 66 85 292