Our Sanitary Divert Valve Auto Control is designed to redirect the flow between different pipelines by auto control, making it ideal for applications where production lines need to be switched between product processes or cleaning cycles. By enabling quick, safe, and hygienic fluid redirection, it plays a vital role in production lines that demand both flexibility and strict sanitary control.

Constructed from high-grade stainless steel 316L, it provides excellent corrosion resistance and durability. The valve features clamp or weld end connections for easy installation and maintenance, and its internal polished surface finish meets stringent sanitary requirements. Furthermore, we offer various flow types to meet specific needs.

- Max. production pressure:10 bar

- Temperature:-10℃ to 140℃ ( EPDM )

- Air pressure:5 bar to 7 bar

- Compressed air:R1/8" ( BSP ), internal thread

- All parts connected with fluid:AISI 316/316L

- Other metal parts:304

- Seal:EPDM / Silicone / Viton ( FKM ) / PTFE

| L | T | Y | F |

|---|---|---|---|

|

|

|

|

| L/L | T/L | L/T | T/T |

|

|

|

|

- The air supply (air pressure)

- The length and dimensions of the air hose

- Number of valves connected to same air hose

- Use of single solenoid valve for serial connection

- Product pressure

Air/Spring (simple effect) or Air/Air (double effect) for auto control can use automatic control box to get signal transfer and complete individual valve control

- Signal transfer:- ⑴ with 10 VDC ~ 30 VDC proximity switch connection: 1 or 2pcs ( PNP or NPN )

- ⑵ or 3A 125 VAC, 30 VDC micro switch connection: 1 or 2pcs

Choose ⑴ or ⑵ + DC24 3.0W electric valve: 1pc & air manifold for complete control box

-

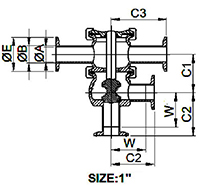

STL-APneumatic Divert Valve T/L-Type

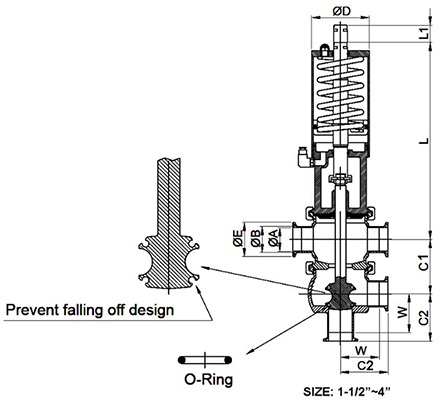

Size ØA ØB ØE ØD C1 C2 C3 W L L1 1” 22.1 25.4 50.5 60 56.7 63.5 81.4 50.8 153.6 17 1-1/2” 34.8 38.1 50.5 85 80.0 69.9 - 57.2 290.0 25 2” 47.5 50.8 64.0 85 92.4 88.9 - 76.2 296.3 25 2-1/2” 60.2 63.5 77.5 133 120.0 88.9 - 76.2 365.8 32 3” 72.9 76.2 94.0 133 128.0 95.3 - 82.6 368.9 36 4” 97.4 101.6 119.0 133 150.8 114.3 - 98.5 645.7 38 -

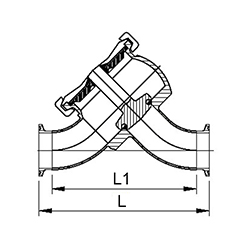

SY-APneumatic Divert Valve Y-Type

SIZE L1 L 1” 96.1 121.5 1-1/2" 142.3 167.7 2” 168.6 194 2-1/2” 211.6 237 3” 244.7 270.1 4” 303.1 334.7

Operation Instruction

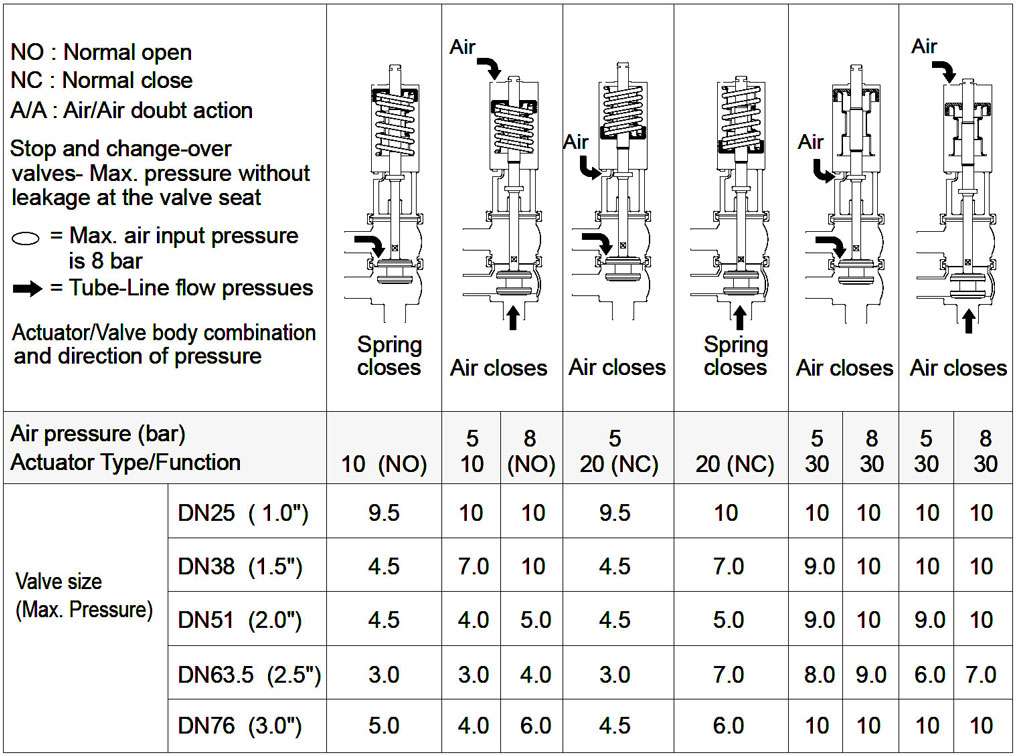

Max. flow tube pressure without leakage of valve seat.

If over table Max. Pressure, adding proof mix. valve is suggested.

Actuator type / function:

(10) SA. Pneumatic downward movement, spring return (NO-lower seat)

(20) AS. Pneumatic upward movement, spring return (NC-lower seat)

(30) AA. Pneumatic upward and downward movement (A/A)